With an ERP (Enterprise Resource Planning) system, all data is centralized in one place. From orders to inbound and outbound sales, supply chain, and inventory management, an ERP for logistics centralizes all data in one place, playing a crucial role in successful supply chain management. Now, you won’t have to search for different data sources to make sense of your logistics information. You can manage it all from a single, cohesive source.

Data about company resources, recorded and centralized in an ERP software, can help forecast and decide on resources like management, inventory, goods, and/or personnel.

ERP software is a game-changer for any business, and it’s definitely something you should be considering for your company. Not convinced yet? Keep on reading!

What's the role of an ERP in a manufacturing business and what can it do for your logistics?

First, let’s get back to basics

An ERP (Enterprise Resource Planning) software integrates various business processes and functions — including finance, human resources, manufacturing, supply chain processes, and logistics — into a centralized database. It offers a unified, comprehensive view of an organization’s data and facilitates efficient resource, operations, and information management. In the logistics context, an ERP system enhances and automates logistics operations by maintaining real-time visibility, control, and optimization across the entire supply chain. It supports accurate demand forecasting, efficient inventory and order processing, transportation planning, warehouse management, and the tracking and tracing of goods.

Improved overall efficiency

An ERP system eliminates redundant tasks, manual processes, and data silos. It supports key supply chain activities such as:

- Planning and Procurement: Streamlines procurement processes to ensure timely availability of materials necessary for production.

- Manufacturing: Integrates with production management tools to optimize production planning, scheduling, and execution.

- Inventory management: Provides tools to manage stock levels effectively, reducing excess or insufficient inventory.

- Order management: Automates order processing to reduce lead times and increase accuracy.

Real-time data recording allows managers to stay updated on inventory status, order progress, and identify any issues with stock levels or delivery failures. Key functionalities enable businesses to:

- Reduce inventory costs.

- Optimize supply chain operations.

- Maximize operational efficiency.

- Ensure on-time delivery of each customer’s order.

- Simplify resource planning.

- Make informed decisions.

Enhanced visibility and control

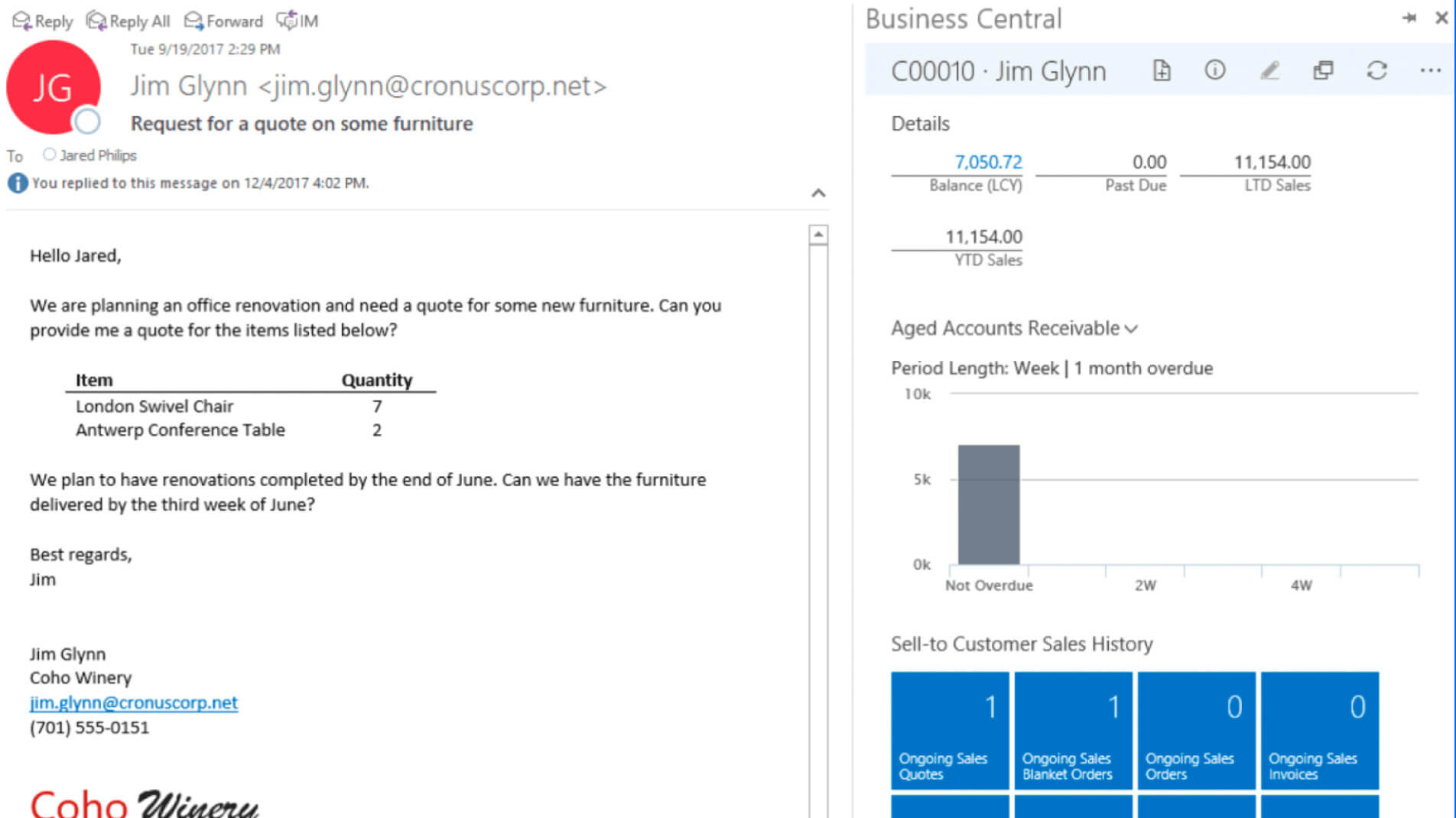

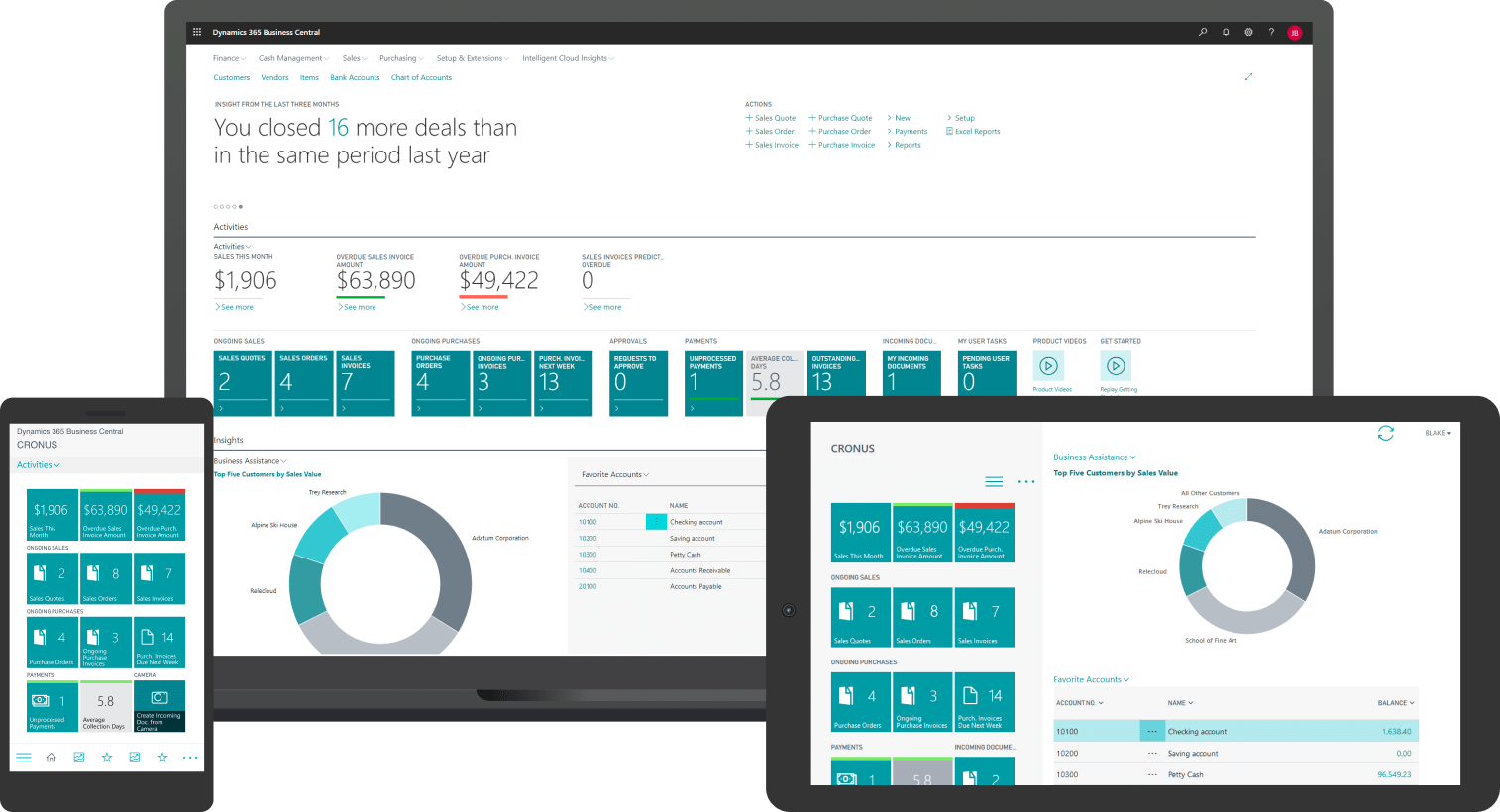

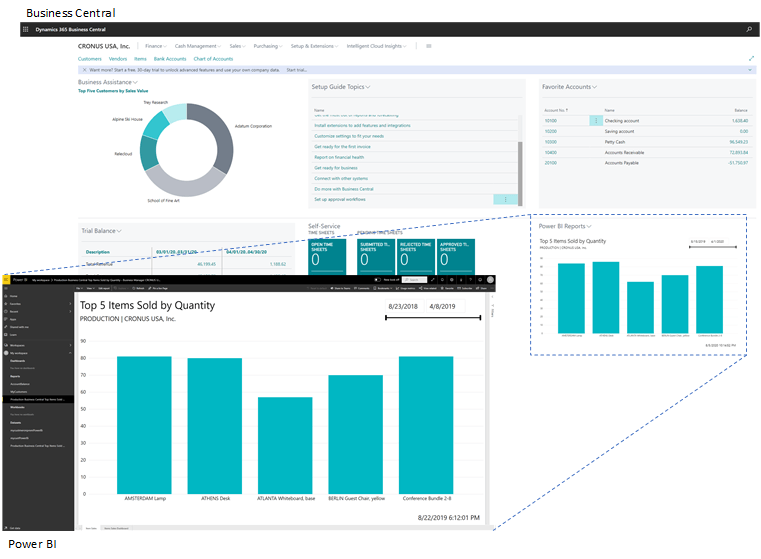

With a logistics ERP system, businesses gain real-time insights into their logistics operations, including inventory levels, order status, shipment tracking, and performance analytics. This visibility enables proactive decision-making, accurate planning, and effective risk management. It also supports working across various devices and platforms, ensuring you can manage your operations from anywhere, whether on desktop, tablet, or mobile, and across different operating systems like Windows, macOS, Android, and iOS.

Cost reduction

By optimizing inventory levels and forecasting demand accurately, an logistics ERP system helps reduce operational costs. Efficient route planning and automation further decrease expenses by reducing manual intervention and enhancing process efficiency. This optimization increases cash flow by rightsizing inventory and maximizing the asset capitalization lifecycle.

Customer satisfaction

A logistics ERP system enhances customer service by ensuring on-time delivery, accurate order fulfillment, and effective communication throughout the supply chain. This not only increases customer satisfaction but also fosters loyalty and encourages repeat business. Features like managing service orders for repairs or replacements, and offering spare equipment during service periods, boost customer loyalty.

Scalability and growth in supply chain management

As businesses grow, an logistics ERP system supports scalability with flexible modules and customization options. The manufacturing industry benefits from ERP integration with other solutions like transportation management systems, customer relationship management, and warehouse management systems. Seamless integration handles increased transaction volumes, adapts to changing market demands, and supports future growth. Purpose-driven extensions, like a Shopify Connector available on platforms like Microsoft AppSource, can meet unique vertical or business-specific requirements.

Regulatory compliance

An ERP system aids in adhering to industry regulations related to logistics, such as customs, trade compliance, product safety, and traceability requirements. It ensures accurate documentation, complete audit trails, and compliance with legal obligations, helping businesses like Bedard enhance their accounting efficiency with integrated solutions like Business Central and Gestisoft.

Business Central x Bédard Ressources

Discover how Bédard Ressources made its accounting more efficient with Business Central

Differences between a logistics ERP and a general ERP

General ERP systems are comprehensive software platforms designed to integrate and manage the primary business functions of an organization, such as finance, HR, manufacturing, and customer relations. The key feature of a general ERP is its broad applicability, enabling it to serve as the central framework for data and processes across various departments. This integration fosters improved decision-making, efficiency, and data consistency throughout the organization.

Logistics ERP systems, on the other hand, are specialized versions of ERP software that focus specifically on optimizing logistics and supply chain management. These systems are tailored to manage complex logistics operations such as inventory management, shipping and receiving, fleet management, and order tracking more effectively. A Logistics ERP provides tools and features specifically designed to handle the nuances of supply chain dynamics, such as route planning, load optimization, and real-time tracking of goods and materials.

Key differences:

- Focus and specialization: While general ERP software serve a broad range of business functions, Logistics ERPs are specialized to efficiently handle specific tasks related to logistics and supply chain management.

- Functionality: Logistics ERPs offer advanced features like warehouse management, detailed shipping logistics, and sophisticated tracking systems that aren’t typically as comprehensive in general ERPs.

- User base: General ERP software are designed for a wide variety of users across an organization, whereas Logistics ERPs are particularly useful for supply chain managers, warehouse operators, and logistics coordinators.

- Impact on operations: A Logistics ERP can significantly reduce transportation costs and improve delivery times, making it essential for businesses where logistics are a critical part of operations.

By choosing a system that aligns with their specific needs, organizations can optimize their processes and achieve greater operational efficiencies.

Some core features of a Logistics ERP software

In today's fast-paced and complex business environment, effective logistics management is more critical than ever. A Logistics ERP software is designed to streamline and optimize every aspect of logistics operations—from inventory management to order fulfillment and beyond. This introductory guide will delve into the core features of Logistics ERP software, illustrating how these functionalities can transform logistics operations, enhance efficiency, and drive business growth. Whether you're looking to improve real-time data accuracy or streamline your supply chain processes, understanding these key features is essential.

Core features of an ERP logistics management system

Inventory lists

Display all your products in a comprehensive list, where you can sort, classify, and organize these goods into groups or classes. This feature includes a detailed display of inventory, cost, weighted average cost, replenishment needs, and inventory history. Specific data for each product can be viewed on display panels if criteria are specified.

- Comprehensive inventory display

- Group and class organization

- Cost and history tracking

Don't forget to read our article on the advantages of ERP inventory management!

Use one or multiple costing methods for inventory items, and easily move items between locations to control the quantity on hand using cycling counting.

Multiple costing methods

Use one or multiple costing methods for inventory items, helping you handle various financial scenarios. Easily transfer items between locations and manage the quantity on hand using cycling counting to ensure accuracy and efficiency in stock levels.

- Various Costing methods

- Item transfer and location management

- Cycling counting for stock accuracy

Variables and details pay off

Add detailed information to each product and product category. Include variants and details such as SKU codes, barcodes, and vendor codes. Manage attributes like size, weight, purchase price options, and track variations in color, units of measure, shelf life, and other attributes to enhance inventory tracking throughout the product lifecycle, from demand planning to customer service.

- SKU codes, barcodes, vendor codes

- Size, weight, purchase price options

- Color, units of measure, shelf life tracking

Product history

Each product features a tracker that records its entire movement history, which is invaluable for effective supply chain management. This tool aids in the replenishment process and supports teams with planning and allocation. It logs dates to track each step from receipt to product shipment, ensuring a comprehensive understanding of each product’s journey.

- Movement history tracking

- Replenishment process sid

- Comprehensive product journey log

Barcode scanner

Implement a barcode scanner to streamline searching and managing inventory. Enter and retrieve details of each item, including order and purchase dates. This system integrates seamlessly with existing barcodes, optimizing your inventory management process.

- Barcode integration

- Item detail management

- Order and purchase date tracking

Replenishment report

Stay ahead with detailed replenishment reports that predict when new supplies will be needed, based on actual demand, sales forecasts, and expected stock-outs. These reports facilitate the automatic creation of purchase orders, streamlining your inventory management.

- Demand-based replenishment

- Sales Forecast integration

- Automated purchase order creation

Running a Smooth organization

Managing your staff can be challenging, especially in a logistics and transportation business. A logistics ERP system simplifies this by enabling you to manage employee hours, lunch breaks, personal information, and track staff locations. Additionally, manage salary increases, bonuses, sick leave, and temporary or seasonal staff. This feature also provides a complete list of staff (permanent or temporary) available in case of emergencies.

- Employee hour and break management

- Personal information and location tracking

- Salary and bonus management

Reducing handling and shipping costs

The accuracy of data provided by an logistics ERP system helps manage expenses effectively, allowing you to identify and reduce major business costs. Make data-driven decisions quickly, avoiding reliance on unsolicited or inaccurate advice. Solve problems as they arise, directly contributing to cost management and significantly reducing business risks. Additionally, maintain perfect logistics with real-time visibility of your operations and instant access to your global supply chains, increasing productivity and operational efficiency.

- Expense identification and reduction

- Data-driven decision making

- Real-time operation visibility

The advantages of an ERP software for managing your logistics

A quick but detailed look at the advantages of such software:

Controlled inventory transfers between warehouses

Effortlessly create and manage inventory transfer documents. This feature allows you to analyze and move your inventory between various warehouses smoothly and predictably, ensuring that transfers are completed without any surprises and always on time.

- Example: A large retail chain uses the system to efficiently transfer seasonal merchandise from a central warehouse to regional stores, thus managing stock levels appropriately and avoiding overstock or shortages.

Efficient inventory reception

Receive inventory at any designated warehouse. You can specify not only the warehouse where you wish to receive the inventory but also its exact location once the order is received.

- Example: An electronics distributor utilizes this feature to ensure that fragile items are directly stored in a secure, environment-controlled area upon arrival, minimizing damage and handling errors.

Order fulfillment from designated warehouses

Specify the exact location from which you wish to ship your goods. The inventory in that particular location will automatically decrease when the sales order is filled, ensuring that your stock levels are always accurate and up-to-date.

- Example: A furniture manufacturer ensures that shipments to the East Coast are dispatched from their closest warehouse to reduce shipping times and costs.

Insights from our manufacturing white paper

Solutions to navigate challenges and drive digital transformation in the Canadian manufacturing industry

Download our white paper

Download our white paper

Real-time inventory data

Utilize real-time data on every item’s zone, bin, and quantity to better fulfill your customers’ orders.

- Example: A fashion retailer manages multiple SKUs and maintains accurate stock levels during peak shopping seasons, like Black Friday, by accessing up-to-date inventory data with the help of their erp software.

Advanced order tracking

Managing order status across multiple warehouses can be complex. However, with logistics ERP software, you can easily track the location and progress of your orders in different warehouses.

- Example: A logistics company prints order lists after the shipping process for optimal management and tracking, ensuring that each shipment meets delivery timelines.

Streamlined warehouse setup and management

Easily set up new warehouses and manage inventory transfers within and between these locations. Deliver or ship sales orders from any warehouse, simplifying the logistics of expanding your operations.

- Example: A business expanding into new markets sets up a new warehouse and integrates it into their existing network without disrupting operations with the help of their erp software.

Comprehensive Warehouse management by location

Manage your warehouses remotely with comprehensive tools that allow you to monitor inventory levels, orders, last purchased items, replenishment rates, profit amounts, and profit margins by location.

- Example: An international distributor uses this feature present in their ERP system to analyze which products are performing best in various regions and adjust their inventory and marketing strategy accordingly.

Cost savings

Logisitics ERP systems are proven to save money. Research indicates that operational and administrative costs can be reduced by up to 23% and 22%, respectively, through the implementation of an ERP system.

- Example: A manufacturing company reduces administrative costs by automating order processing and customer billing, thereby eliminating manual errors and reducing staffing needs with an ERP system.

Customization capabilities

Companies that require tailor-made solutions have the freedom to customize their ERP system to fit their specific needs perfectly.

- Example: an automotive parts distributor customizes their logistics ERP to optimize their supply chain and inventory management, ensuring timely deliveries and reducing storage costs.

Beyond business as usual: the ERP transformation

An ERP system is pivotal in enabling optimal inventory management, which is a cornerstone of an effective business management strategy. But the benefits extend far beyond that. Implementing the right ERP system not only streamlines your logistics with various software tools but also saves significant time.

With your warehouse inventory well organized, ERP software provides both product traceability and efficient employee management. Having access to comprehensive data on every aspect of production allows you to optimize costs and boost employee productivity.

Moreover, you'll gain the capability to promptly identify any issues within your production line, enhancing operational efficiency across the board.

Choosing the right Logistics ERP solution tailored to your specific needs can transform your company’s productivity and drastically reduce costs. Contact us to explore how a customized ERP solution can meet your unique operational requirements and propel your business forward.

Ready to transform your logistics operations?

Discover how our logistics ERP software can streamline your supply chain and improve operational efficiency. Don’t miss out on the opportunity to optimize your logistics processes. Contact us today to learn more and see how we can tailor our solution to meet your specific needs. Let’s take the first step towards a more efficient and productive future together!

Contact Sales

Contact Sales

Liked what you just read? Sharing is caring.

June 17, 2025 by Kooldeep Sahye by Kooldeep Sahye Marketing Specialist

Fuelled by a passion for everything that has to do with search engine optimization, keywords and optimization of content. And an avid copywriter who thrives on storytelling and impactful content.