In today's fast-paced business environment, companies need efficient systems to manage their operations, streamline processes, and enhance productivity. Two of the most popular systems designed to achieve these goals are ERP vs MRP. While both systems play crucial roles in business management, they serve different purposes and offer distinct advantages.

Choosing the right system—whether ERP vs MRP—can significantly impact your business's efficiency and success. This article aims to shed light on the key differences between ERP vs MRP, helping you make an informed decision that aligns with your business.

What is an ERP (Enterprise Resource Planning)?

ERP (Enterprise Resource Planning) is comprehensive business management software that integrates various organizational functions and processes into a single system. By unifying people, processes, and technologies, ERP systems reduce duplication, streamline operations, improve data accuracy, and enhance productivity. They handle diverse activities, including finance, HR, supply chain, and customer relationship management. In the context of ERP vs MRP, ERP provides a holistic approach to managing multiple departments and functions.

Key Features and Functionalities of ERP software

Integration: ERP systems unify different business processes and data into one platform, ensuring seamless communication and consistency across departments. Both ERP and MRP systems enhance integration and information sharing, improving collaboration and data flow across various functions. This integration enables efficient data flow between departments such as sales, finance, procurement, and manufacturing, reducing silos and fostering collaboration. For example:

- Sales and Inventory Integration: When a sales order is placed, the ERP system can automatically update inventory levels, initiate procurement processes, and generate an invoice without any manual intervention.

- Finance and HR Integration: Payroll processes can be linked with financial accounting, ensuring accurate salary payments and financial reporting.

Real-Time Data and Analytics With an ERP (enterprise resource planning), businesses can access real-time data and analytics, facilitating better decision-making and responsiveness. Real-time insights enable companies to monitor performance, track key metrics, and make informed decisions quickly. For instance:

- Inventory Management: Real-time inventory data can help a retail business prevent stockouts and overstock situations, optimizing stock levels based on actual demand.

- Financial Reporting: Real-time financial dashboards provide up-to-date information on revenue, expenses, and profitability, enabling timely strategic decisions.

Scalability ERP solutions are scalable, making them suitable for businesses of all sizes and industries. As a company grows, its ERP software can be expanded to accommodate additional users, functions, and geographic locations. This scalability ensures that the system can support the business’s evolving needs without requiring a complete overhaul. For example:

- Expanding Operations: A growing manufacturing company can add new production facilities and integrate them into the existing ERP system, maintaining a unified view of operations.

- Adding Modules: Businesses can start with core modules and later add functionalities like CRM, advanced analytics, or e-commerce as they grow.

Customization Many ERP systems offer customization options to meet the specific needs of different businesses. Companies can tailor the software to align with their unique processes, workflows, and industry requirements. Customization helps businesses maximize the value of their ERP software by ensuring it fits seamlessly into their operations. For instance:

- Healthcare Customization: A healthcare provider might customize its ERP system to manage patient records, appointment scheduling, and regulatory compliance.

- Manufacturing Customization: A manufacturer can customize production planning modules to match their specific manufacturing processes and requirements.

Automation ERP automates routine tasks and processes, reducing manual effort and minimizing errors. Automation capabilities extend to various functions, such as invoicing, payroll, inventory management, and order processing. By automating repetitive tasks, businesses can free up employees’ time for more strategic activities, improving overall efficiency. For example:

- Payroll Processing: Automated payroll processing ensures accurate and timely salary payments, reducing the risk of human error and ensuring compliance with labor laws.

- Order Processing: Automated order processing can streamline the sales cycle, from order entry to delivery, enhancing customer satisfaction.

Compliance and Reporting ERP software assist businesses in maintaining compliance with industry regulations and standards. They provide robust reporting tools that generate accurate and timely reports, ensuring that companies meet regulatory requirements and internal policies. This feature is crucial for industries with stringent compliance standards, such as finance, and manufacturing. For example:

- Financial Compliance: ERP softwares can generate audit-ready financial reports, helping businesses comply with accounting standards and regulations.

Enhanced Customer Service With integrated customer relationship management (CRM) functionalities, ERP systems help businesses improve customer service and satisfaction. CRM features allow companies to track customer interactions, manage inquiries, and provide personalized service. By having a 360-degree view of customer data, businesses can build stronger relationships and drive customer loyalty. For instance:

- Service Management: A service-based company can use CRM data to respond to customer inquiries more effectively and offer tailored solutions based on customer history.

- Sales Insights: Sales teams can access detailed customer profiles and interaction history to personalize their sales approach and improve conversion rates.

Resource Optimization ERP systems enable businesses to optimize the use of their resources, including human capital, financial assets, and physical inventory. By providing visibility into resource allocation and utilization, ERP helps companies identify inefficiencies and implement corrective actions. This optimization leads to cost savings and better resource management. For example:

- Project Management: An ERP system can help manage project resources, ensuring that materials and labor are allocated efficiently to meet project deadlines and budgets.

- Inventory Optimization: Automated inventory management helps businesses maintain optimal stock levels, reducing holding costs and minimizing the risk of stockouts.

In the comparison of ERP vs MRP, it is evident that ERP systems offer a broader scope of functionalities, encompassing various aspects of business management beyond just manufacturing and inventory control. This wide-ranging applicability makes ERP an ideal choice for companies looking for an integrated solution to manage their entire operations.

What is an MRP?

MRP (Material Requirements Planning), also known as manufacturing resource planning, is a system designed to manage manufacturing processes by ensuring that materials and products are available for production and delivery to customers. Unlike ERP, which covers a broad range of business functions, MRP focuses specifically on production planning, inventory control, and scheduling. In the context of ERP vs MRP, MRP systems are crucial for manufacturers looking to optimize their production processes and maintain efficient inventory levels.

Key Features and Functionalities of MRP softwares

Inventory Management : They excel in managing inventory by determining what materials are needed, in what quantities, and when they are required. This helps in minimizing inventory levels while ensuring that production schedules are met. For example:

- Demand Forecasting: They use historical sales data and forecasts to predict future material requirements, helping businesses maintain optimal inventory levels.

- Reorder Point Calculation: The system automatically calculates reorder points based on lead times and demand patterns, triggering purchase orders when inventory levels fall below a certain threshold.

Production Planning : They assist in planning and scheduling production activities, ensuring that manufacturing processes run smoothly and efficiently. For instance:

- Master Production Schedule (MPS): The MPS outlines what products need to be produced, the quantities, and the timelines, providing a detailed production plan that aligns with customer demand.

- Capacity Planning: They assess the capacity of production resources, such as labor and machinery, to ensure that production schedules are realistic and achievable.

Bill of Materials (BOM) The BOM is a comprehensive list of raw materials, components, and assemblies required to manufacture a product. MRP softwares manage BOMs to ensure that all necessary materials are available for production. For example:

- BOM Explosion: The system breaks down the BOM into individual components and calculates the quantities needed for production, ensuring that all materials are accounted for.

- BOM Management: They track changes to BOMs, allowing manufacturers to update materials and processes as needed to improve efficiency and reduce costs.

Lead Time Management Managing lead times is critical for ensuring that materials are available when needed without causing delays in production. MRP systems help in accurately calculating and managing lead times. For instance:

- Supplier Lead Times: The system tracks lead times for materials from suppliers, helping businesses plan orders to ensure timely delivery.

- Production Lead Times: They calculate the time required to produce goods, including setup times, processing times, and queue times, ensuring that production schedules are met.

Demand Management The software help businesses manage and respond to customer demand by aligning production schedules with sales orders and forecasts. For example:

- Sales Order Management: The system integrates with sales order processing to ensure that production schedules align with customer demand, reducing the risk of overproduction or stockouts.

- Forecasting Integration: The system use sales forecasts to anticipate future demand, allowing manufacturers to plan production and inventory levels accordingly.

Procurement Management The system streamline the procurement process by automating purchase orders and ensuring that materials are ordered in the right quantities and at the right time. For instance:

- Automatic Purchase Orders: When inventory levels reach reorder points, the system automatically generates purchase orders, reducing manual effort and ensuring timely procurement.

- Supplier Management: The software track supplier performance, including delivery times and order accuracy, helping businesses manage supplier relationships and improve procurement efficiency.

Cost Control : The system assist in controlling manufacturing costs by optimizing material usage and minimizing waste. For example:

- Material Cost Analysis: The system tracks material costs and usage, providing insights into cost-saving opportunities and helping businesses manage their production budgets.

- Waste Reduction: By accurately planning material requirements and production schedules, MRP systems help reduce waste and improve overall manufacturing efficiency.

Production Tracking MRP systems provide real-time visibility into production processes, allowing manufacturers to monitor progress and identify potential issues. For instance:

- Work-in-Progress (WIP) Tracking: The system tracks the status of production orders and WIP, ensuring that production schedules are adhered to and any delays are promptly addressed.

- Quality Control: MRP systems integrate with quality control processes to ensure that products meet specified standards, reducing the risk of defects and rework.

Examples of popular MRP software include SAP MRP, Oracle MRP, and Microsoft Dynamics MRP. These systems are designed to meet the specific needs of manufacturers, providing tools and functionalities that enhance production efficiency and inventory management.

In the comparison of ERP vs MRP, MRP softwares are specialized tools that focus on the manufacturing sector, offering detailed functionalities for production planning, inventory control, and procurement management. This specialization makes MRP an ideal choice for manufacturing businesses seeking to optimize their production processes and maintain efficient inventory levels.

Key Differences Between ERP and MRP

When evaluating ERP or MRP system, it is essential to understand the differences between these two systems to determine which one is best suited for your business needs. While both systems are designed to improve business efficiency and productivity, they differ significantly in their scope, integration capabilities, flexibility, and scalability.

Scope and Coverage

ERP: Comprehensive Business Management ERP softwares offer a comprehensive approach to managing various aspects of a business, covering a wide range of functions such as finance, human resources, supply chain, customer relationship management, and manufacturing. This broad coverage allows businesses to integrate all their processes into a single system, providing a unified view of operations.

- Finance: Manages accounting, financial reporting, budgeting, and asset management.

- Human Resources: Handles payroll, employee records, recruitment, and performance management.

- Supply Chain Management: Oversees procurement, inventory, logistics, and supplier relationships.

- Customer Relationship Management (CRM): Manages customer data, sales processes, and customer service.

- Manufacturing: Coordinates production schedules, material requirements, and quality control.

MRP: Focus on Manufacturing and Inventory Management MRP systems, on the other hand, are specifically designed to manage manufacturing processes and inventory control. They focus on ensuring that materials are available for production, production schedules are optimized, and inventory levels are maintained efficiently. In the debate of ERP vs MRP, MRP excels in its specialized focus.

- Material Requirements Planning: Calculates the materials needed for production and schedules procurement.

- Production Planning: Develops production schedules to meet customer demand.

- Inventory Control: Manages stock levels to minimize excess inventory and prevent shortages.

- Procurement Management: Automates the purchasing process to ensure timely availability of materials.

Integration Capabilities

ERP: Integrates Various Business Processes ERP systems excel in integrating various business processes into a single platform, ensuring seamless communication and data flow across departments. This integration helps eliminate data silos, improve collaboration, and provide real-time visibility into business operations. In terms of ERP vs MRP, ERP offers broader integration capabilities.

- Unified Data: Combines data from different departments into a single database.

- Automated Workflows: Streamlines processes such as order-to-cash and procure-to-pay.

- Real-Time Updates: Ensures that changes in one department are immediately reflected in others.

- Collaboration Tools: Provides tools for cross-departmental communication and project management.

MRP: Primarily Integrates Manufacturing Processes While MRP systems integrate manufacturing processes, their integration capabilities are more limited compared to ERP systems. MRP focuses on linking production planning, inventory management, and procurement, ensuring that materials and production schedules are aligned.

- Production Scheduling: Synchronizes production activities with material availability.

- Inventory Synchronization: Ensures that inventory levels are updated based on production needs.

- Procurement Integration: Aligns purchase orders with production requirements to avoid delays.

Flexibility and Scalability

ERP: Scalable and Flexible for Different Industries ERP systems are highly scalable and flexible, making them suitable for businesses of all sizes and industries. They can be customized to meet the specific needs of different organizations and can be expanded as the business grows. This scalability ensures that the ERP system can support the business's evolving needs without requiring a complete overhaul. This is a key consideration in the ERP vs MRP comparison.

- Modular Design: Allows businesses to start with core modules and add more as needed.

- Industry-Specific Solutions: Provides tailored solutions for industries such as healthcare, manufacturing, retail, and finance.

- Cloud-Based Options: Offers scalability and remote access through cloud-based deployment.

- Customizable Workflows: Enables businesses to configure processes according to their unique requirements.

MRP: Tailored for Manufacturing Operations MRP systems are tailored specifically for manufacturing operations, providing specialized tools and functionalities that cater to the needs of manufacturers. While MRP systems can handle complex production environments and large-scale manufacturing operations, their focus is primarily on optimizing manufacturing processes rather than providing a broad range of business management capabilities.

- Manufacturing Focus: Designed specifically for production planning and material control.

- Specialized Tools: Includes features such as BOM management, capacity planning, and shop floor control.

- Efficient Scheduling: Optimizes production schedules to reduce lead times and increase efficiency.

- Inventory Optimization: Minimizes excess inventory while ensuring material availability for production.

Examples of both systems :

ERP Systems:

- SAP ERP: A comprehensive ERP solution that integrates various business processes, including finance, HR, and supply chain management.

- Oracle ERP Cloud: A scalable and flexible ERP system that offers a wide range of functionalities for different industries.

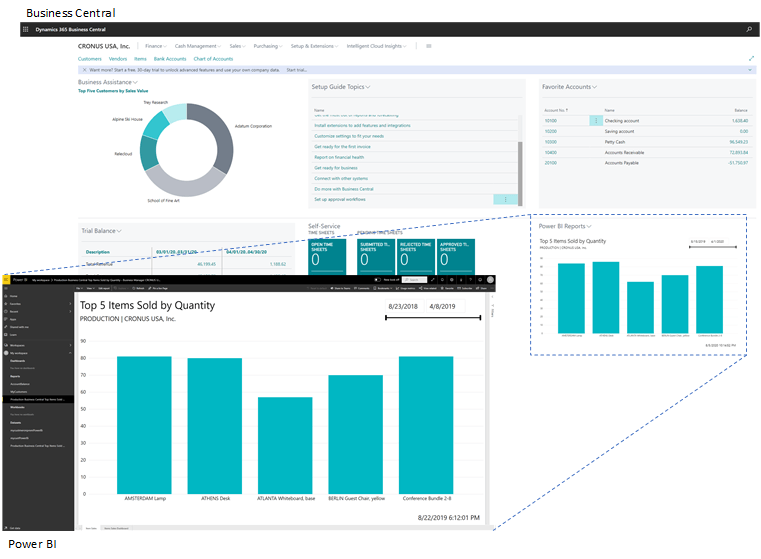

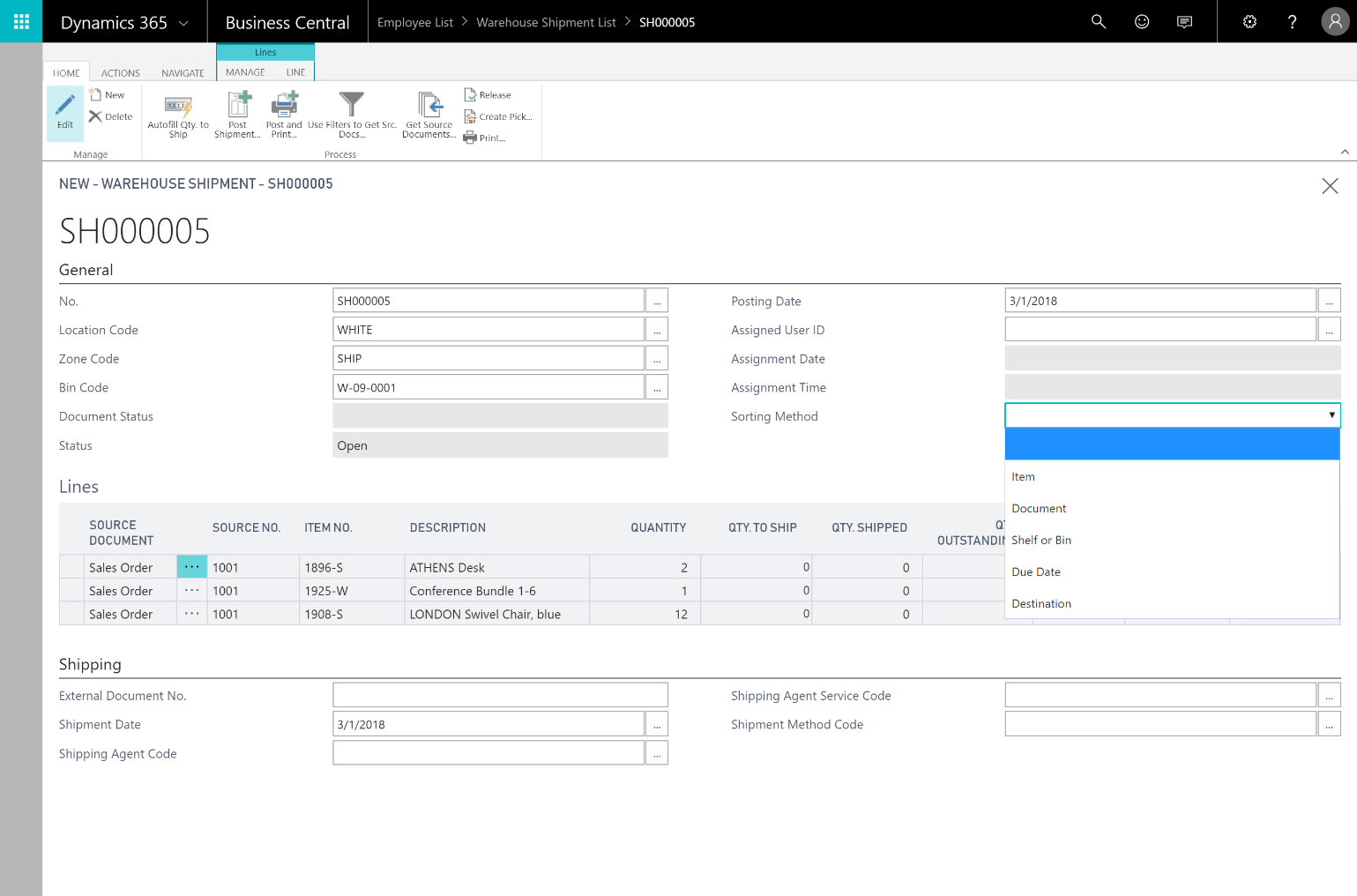

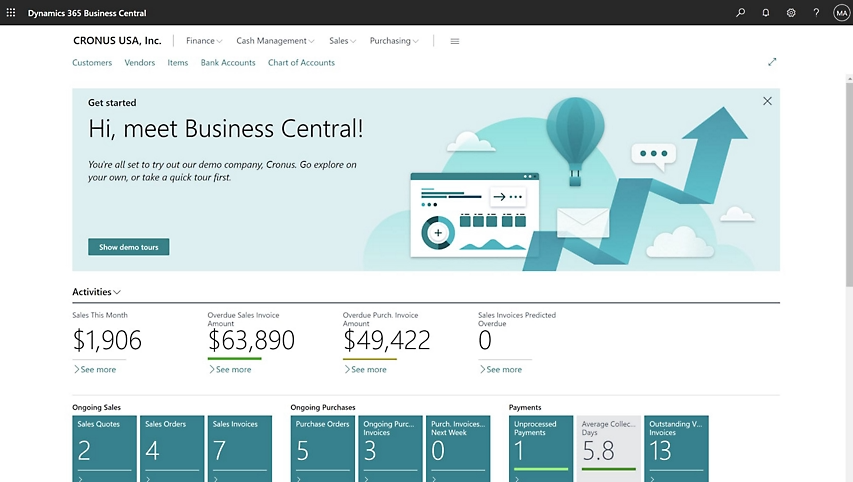

- Microsoft Dynamics 365 Business Central: An ERP solution designed for small and medium-sized businesses, providing integrated tools for finance, sales, and operations.

MRP Systems:

- SAP MRP: A specialized MRP module within the SAP suite that focuses on production planning and material requirements.

- Oracle MRP: A component of Oracle's manufacturing solutions, providing detailed functionalities for inventory control and production scheduling.

- Microsoft Dynamics MRP: An MRP solution that integrates with Microsoft Dynamics ERP systems, offering tools for managing manufacturing processes and inventory.

In conclusion, the key differences between ERP vs MRP lie in their scope, integration capabilities, flexibility, and scalability. ERP systems offer a comprehensive solution for managing various business functions, making them ideal for companies looking for an integrated approach to business management. MRP systems, on the other hand, are specialized tools for optimizing manufacturing processes and inventory control, making them suitable for manufacturers seeking to improve production efficiency.

Case study

Discover how Bédard Ressources made its accounting more efficient with Business Central

Pros and Cons of ERP

When evaluating ERP vs MRP, it is crucial to understand the advantages and disadvantages of ERP systems to determine if they are the right fit for your business. ERP systems offer extensive benefits but also come with certain challenges.

Advantages of ERP

Integrated Business Processes

- Benefit: ERP systems unify various business functions into a single platform, ensuring seamless communication and data flow across departments.

- Example: Automatically updating inventory levels, generating invoices, and updating financial records when a sales order is placed, ensuring that all departments have access to the latest information.

Real-Time Data and Analytics

- Benefit: Provides real-time data and analytics, enabling informed and timely decision-making.

- Example: Retail businesses can use real-time inventory data to optimize stock levels, preventing stockouts and overstock situations.

Scalability and Flexibility

- Benefit: ERP systems are highly scalable and flexible, suitable for businesses of all sizes and industries, and can be customized to meet specific needs.

- Example: A small business can start with core ERP modules and gradually add more functionalities like CRM or advanced analytics as it grows.

Automation

- Benefit: Automates routine tasks and processes, reducing manual effort and minimizing errors.

- Example: Automated payroll processing ensures accurate and timely salary payments, reducing the risk of human error and ensuring compliance with labor laws.

Compliance and Reporting

- Benefit: Helps maintain compliance with industry regulations and standards through robust reporting tools.

- Example: A pharmaceutical company can track and document compliance with FDA regulations, ensuring product quality and safety.

Enhanced Customer Service and Supply Chain Management

- Benefit: Integrated CRM functionalities improve customer service and satisfaction by providing personalized service.

- Example: Service-based companies can use CRM data to respond to customer inquiries more effectively and offer tailored solutions based on customer history.

Resource Optimization

- Benefit: Optimizes the use of resources, including human capital, financial assets, and inventory.

- Example: A construction company can manage project resources efficiently, ensuring materials and labor are allocated to meet deadlines and budgets.

Disadvantages of ERP

Complexity and Cost of Implementation

- Challenge: ERP systems can be complex and expensive to implement, requiring significant investment in software, hardware, and consulting services.

- Example: A large corporation may need extensive training, data migration, and process reengineering, leading to high upfront costs.

Significant Training and Change Management

- Challenge: Adopting an ERP system requires substantial training and effective change management to ensure a smooth transition.

- Example: Employees used to legacy systems may need extensive training to adapt, and the company must invest in change management initiatives.

Customization and Maintenance Challenges

- Challenge: Customizing ERP software to meet specific business needs can be complex and costly, with maintenance and updates posing additional challenges.

- Example: A heavily customized ERP system may face difficulties when upgrading to new software versions, requiring extra resources for maintenance.

Risk of Implementation Failure

- Challenge: ERP implementations can be risky, with potential for scope creep, budget overruns, and missed deadlines.

- Example: Without adequate planning, a company may encounter delays, cost overruns, and operational disruptions, leading to a failed project.

In the context of ERP vs MRP, it is important to weigh the pros and cons of ERP systems carefully. While ERP systems offer comprehensive solutions and significant benefits, they also demand careful planning, investment, and management to ensure successful implementation and operation.

Pros and Cons of MRP

When comparing ERP vs MRP, it’s essential to understand the advantages and disadvantages of MRP systems. While MRP systems offer specialized benefits for manufacturing operations, they also come with specific limitations.

Advantages of MRP

Specialized for Manufacturing Needs

- Benefit: MRP systems are specifically designed to address the needs of manufacturing businesses, providing tools tailored to production planning and inventory management.

- Example: A manufacturing company can use an MRP system to ensure that the right materials are available at the right time, optimizing production schedules and reducing downtime.

Efficient Inventory Management

- Benefit: MRP systems help maintain optimal inventory levels by calculating material requirements based on production schedules and demand forecasts.

- Example: By using demand forecasting, an MRP system can prevent overstocking and stockouts, ensuring that materials are available just in time for production.

Improved Production Planning

- Benefit: MRP systems streamline production planning, ensuring that production schedules align with customer demand and resource availability.

- Example: The Master Production Schedule (MPS) feature in MRP systems helps manufacturers plan what products to produce, in what quantities, and when to produce them.

Cost-Effective for Smaller Manufacturers

- Benefit: MRP systems can be more cost-effective than ERP systems for smaller manufacturers with limited operations, focusing solely on production and inventory management.

- Example: A small manufacturing business may find an MRP system more affordable and easier to implement than a comprehensive ERP solution.

Enhanced Procurement Management

- Benefit: MRP systems automate procurement processes, ensuring timely ordering of materials and components required for production.

- Example: Automatic purchase order generation based on reorder points helps maintain a smooth supply chain and reduces the risk of production delays.

Detailed BOM Management

- Benefit: MRP systems efficiently manage Bills of Materials (BOM), tracking all the components and materials required for production.

- Example: The BOM explosion feature breaks down materials needed for each product, ensuring accurate material planning and usage.

Disadvantages of MRP

Limited Scope

- Challenge: MRP systems primarily focus on manufacturing and inventory management, lacking the broader business management capabilities of ERP systems.

- Example: While MRP systems excel in production planning, they may not provide integrated solutions for finance, HR, or customer relationship management.

Integration Challenges

- Challenge: MRP systems may face challenges integrating with other business processes and systems, potentially leading to data silos.

- Example: A company using separate systems for finance and HR might struggle to synchronize data between the MRP system and other software, leading to inefficiencies.

Scalability Issues

- Challenge: MRP systems may not scale as effectively as ERP systems, making them less suitable for rapidly growing businesses with diverse needs.

- Example: As a small manufacturing company expands, it might outgrow its MRP system and require a more comprehensive ERP solution to manage its operations.

Limited Customization

- Challenge: MRP systems may offer fewer customization options compared to ERP systems, restricting their ability to adapt to unique business processes.

- Example: A manufacturer with unique production workflows may find it challenging to customize an MRP system to fully support its operations.

Data Redundancy and Errors

- Challenge: Without proper integration, MRP systems can lead to data redundancy and errors, as information must be manually transferred between systems.

- Example: Manual data entry between the MRP system and other business systems increases the risk of errors and inconsistencies.

Dependency on Accurate Data

- Challenge: MRP systems rely heavily on accurate data inputs to function effectively. Any errors in data entry can disrupt production planning and inventory management.

- Example: Inaccurate demand forecasts or inventory counts can lead to production delays, stockouts, or excess inventory.

In the context of ERP vs MRP, it’s crucial to consider these pros and cons when deciding which system best fits your business needs. MRP systems offer significant benefits for manufacturing operations but may not provide the comprehensive functionality required by businesses seeking an integrated approach to overall business management.

When to Choose ERP ?

Deciding between ERP vs MRP can be challenging, but understanding the scenarios where ERP systems are more suitable can help you make an informed decision. ERP systems offer a comprehensive solution for businesses looking to integrate multiple functions and streamline operations across the organization.

Scenarios Where ERP is More Suitable

1. Businesses Looking for Comprehensive Solutions

- Scenario: Companies that require an all-encompassing system to manage various business functions such as finance, HR, supply chain, and customer relationship management.

- Example: A mid-sized retail company needs a system to handle everything from inventory management and sales to accounting and employee payroll. An ERP system like Microsoft Dynamics 365 Business Central can provide an integrated solution, offering modules for each of these functions.

2. Companies with Complex and Diverse Operations

- Scenario: Organizations with complex operations that span multiple departments, locations, or business units.

- Example: A multinational corporation with manufacturing plants, distribution centers, and sales offices worldwide can benefit from an ERP system like SAP ERP. This system can integrate all locations and functions, providing a unified view of global operations and facilitating efficient coordination.

3. Organizations Needing Integration Across Departments

- Scenario: Businesses that require seamless integration and data flow between different departments to improve efficiency and decision-making.

- Example: A service-based company that needs to integrate its project management, billing, and customer service departments can use an ERP system like Oracle ERP Cloud. This integration ensures that project updates automatically trigger billing processes and customer service actions, enhancing overall efficiency.

4. Growing Companies Planning for Future Expansion

- Scenario: Companies anticipating significant growth that need a scalable system to support their expanding operations.

- Example: A small tech startup planning to expand its product lines and market reach can implement an ERP system like NetSuite. This system's scalability allows the startup to add new functionalities and users as the business grows, ensuring continuous support for its expanding operations.

5. Businesses Requiring Advanced Reporting and Analytics

- Scenario: Organizations that rely on advanced reporting and analytics to make data-driven decisions and improve business performance.

- Example: A financial services firm needing detailed financial analysis, risk management, and compliance reporting can benefit from an ERP system like SAP S/4HANA. The system's advanced analytics and real-time reporting capabilities provide valuable insights for strategic decision-making.

6. Companies Seeking Process Standardization

- Scenario: Businesses aiming to standardize processes across multiple departments or locations to ensure consistency and improve efficiency.

- Example: A manufacturing company with plants in different regions can use an ERP system like Epicor ERP to standardize production processes, quality control, and compliance procedures across all locations. This standardization helps maintain consistent product quality and operational efficiency.

Insights from our manufacturing white paper

Solutions to navigate challenges and drive digital transformation in the Canadian manufacturing industry

Download our white paper

Download our white paper

Key Benefits of Choosing ERP

- Holistic View of Business Operations: Provides a unified view of all business processes, enabling better coordination and decision-making.

- Improved Collaboration: Facilitates seamless communication and collaboration between departments, reducing silos and enhancing teamwork.

- Enhanced Efficiency: Automates routine tasks and processes, reducing manual effort and minimizing errors.

- Real-Time Insights: Offers real-time data and analytics, enabling timely and informed decision-making.

- Scalability: Supports business growth by allowing the addition of new functionalities and users as needed.

- Regulatory Compliance: Helps maintain compliance with industry regulations and standards through robust reporting and audit capabilities.

In the context of ERP vs MRP, ERP systems are ideal for businesses looking for a comprehensive, integrated solution to manage various functions and support growth. ERP systems provide the flexibility, scalability, and advanced capabilities needed to streamline operations, improve efficiency, and drive business success.

When to Choose MRP

Understanding the contexts where ERP vs MRP applies best can guide you to make the right decision. MRP systems are particularly beneficial for businesses focused on manufacturing and inventory management, providing specialized tools to optimize production processes.

Scenarios Where MRP is More Suitable

1. Manufacturing-Focused Businesses

- Scenario: Companies whose primary operations involve manufacturing and production.

- Example: A small manufacturing company producing custom metal parts can use an MRP system to manage its production schedules, material requirements, and inventory levels efficiently. An MRP system like SAP MRP helps ensure that materials are available when needed, reducing downtime and optimizing production.

2. Smaller Companies with Limited Operations

- Scenario: Smaller businesses with straightforward operations that do not require a comprehensive business management system.

- Example: A family-owned bakery that needs to manage raw materials and production schedules but does not need extensive financial or HR functionalities can benefit from an MRP system. The bakery can use an MRP system to ensure it always has the right amount of ingredients on hand and can efficiently schedule baking times.

3. Firms Prioritizing Inventory and Production Management

- Scenario: Businesses that prioritize efficient inventory control and production planning over other business functions.

- Example: A toy manufacturer facing challenges with inventory management and production scheduling can use an MRP system like Oracle MRP. This system helps the manufacturer plan material purchases accurately, maintain optimal inventory levels, and ensure timely production to meet customer demand.

4. Companies with Simple Organizational Structures

- Scenario: Organizations with straightforward, uncomplicated business processes that do not require extensive integration across multiple departments.

- Example: A single-site garment factory that focuses solely on production and material procurement can use an MRP system to streamline its operations. The factory can manage fabric inventory, production schedules, and procurement processes without needing a complex ERP system.

5. Businesses Seeking Cost-Effective Solutions

- Scenario: Companies looking for a cost-effective solution specifically for manufacturing and inventory management, without the need for broader business functionalities.

- Example: A startup producing electronic gadgets on a tight budget can implement an MRP system to manage its production processes and inventory. The cost savings from using an MRP system over a comprehensive ERP system allow the startup to allocate resources to other critical areas of growth.

6. Industries with High Volume, Low Complexity Production

- Scenario: Industries that produce large quantities of products with relatively simple production processes and minimal customization.

- Example: A food processing plant producing canned goods in large volumes can use an MRP system to manage its production schedules and material requirements efficiently. The plant can ensure that raw materials are available in the right quantities and that production runs smoothly to meet demand.

Optimize your ERP software performance by identifying potential areas for improvement through our practical guide.

ERP self-evaluating guide

Key Benefits of Choosing MRP

- Specialized for Manufacturing: Tailored specifically for production planning and material control, making it ideal for manufacturing-focused businesses.

- Efficient Inventory Management: Helps maintain optimal inventory levels, preventing overstocking and stockouts.

- Improved Production Scheduling: Streamlines production planning and scheduling, ensuring that production processes run smoothly and efficiently.

- Cost-Effective: Offers a more affordable solution for smaller businesses or those with limited operations compared to comprehensive ERP systems.

- Detailed BOM Management: Efficiently manages Bills of Materials (BOM), ensuring accurate material planning and usage.

- Enhanced Procurement Management: Automates procurement processes, ensuring timely ordering of materials and components required for production.

In the context of ERP vs MRP, MRP systems are ideal for businesses that focus primarily on manufacturing and inventory management. MRP systems provide the specialized tools and functionalities needed to optimize production processes, maintain efficient inventory levels, and ensure smooth operations. For businesses with straightforward operations and a strong focus on manufacturing, MRP offers a cost-effective and efficient solution.

Choosing between ERP vs MRP is a critical decision that can significantly impact your business’s efficiency, productivity, and overall success. Both systems offer distinct advantages and are suited to different business needs. Understanding the key differences, benefits, and implementation considerations can help you make an informed choice.

Recap of Main Points

ERP Systems:

- Comprehensive Scope: ERP systems provide a holistic approach to managing various business functions, including finance, HR, supply chain, CRM, and manufacturing.

- Integration Capabilities: They integrate multiple departments into a single platform, ensuring seamless data flow and improving overall efficiency.

- Scalability and Flexibility: ERP systems are scalable and customizable, making them suitable for businesses of all sizes and industries.

- Advanced Features: They offer advanced analytics, real-time data, and automation, enhancing decision-making and operational efficiency.

- Ideal For: Companies with complex and diverse operations, those seeking comprehensive solutions, and businesses planning for growth.

MRP Systems:

- Specialized Focus: MRP systems are designed specifically for manufacturing and inventory management, providing tools tailored to production planning and material control.

- Efficient Production Planning: They optimize production schedules, manage inventory levels, and ensure timely procurement of materials.

- Cost-Effective: MRP systems are often more affordable for smaller manufacturers with limited operations.

- Ideal For: Manufacturing-focused businesses, smaller companies with straightforward operations, and firms prioritizing inventory and production management.

Importance of Understanding Business Needs

Selecting the right system—whether ERP vs MRP—requires a thorough understanding of your business’s specific needs, processes, and goals. Here are some key considerations:

- Assess Your Current Processes: Evaluate your existing workflows to identify areas for improvement and determine which system can best address those needs.

- Define Your Objectives: Clearly outline your business objectives and what you aim to achieve with the new system, such as improved efficiency, reduced costs, or better data visibility.

- Consider Your Resources: Assess your budget, technical infrastructure, and the availability of skilled personnel to manage the implementation and ongoing support.

- Plan for the Future: Consider your business’s growth plans and choose a system that can scale and adapt to your evolving needs.

Encouragement to Consult with Experts

Making an informed decision about ERP vs MRP can be complex, and seeking expert advice can provide valuable insights and guidance. Here’s why consulting with professionals is beneficial:

- Expertise and Experience: Consultants with experience in ERP and MRP implementations can help you navigate the selection process, identify the right solution, and ensure a successful deployment.

- Tailored Recommendations: Professionals can provide recommendations tailored to your specific business needs, industry requirements, and operational goals.

- Implementation Support: Expert guidance can help you manage the implementation process, from initial assessment and planning to data migration, training, and ongoing support.

Final Thoughts

Choosing between ERP vs MRP is a strategic decision that can shape the future of your business. By understanding the differences, benefits, and challenges of each system, you can make an informed choice that aligns with your business goals and drives long-term success.

Contact Us for a Free Consultation

Ready to choose the right solution for your business? Contact us today for a free consultation! Our experts are here to help you determine whether an ERP or MRP system is best suited for your needs and guide you through the selection process. Reach out now to get started and optimize your business operations.

Free discovery call

Free discovery call

Liked what you just read? Sharing is caring.

June 11, 2024 by Arianne Pellerin by Arianne Pellerin Marketing Specialist

Driven by an unwavering obsession to optimize processes and revolutionize marketing with innovative ideas, I never stop searching for the perfect solution. My true passion lies in crafting dreamlike experiences by harnessing the full potential of web analytics and cutting-edge digital strategies. As a blog writer for Gestisoft, I bring this expertise to the forefront, focusing primarily on our ERP solutions.